Lifting an object weighing up to 150 kg (330lb) with one Labor Saving Arm equipped with optional 6 mm thick baseplates and bars (standard today is 5 mm) should not be a problem. Lifting of heavier objects is not covered by the product warranty. Please see maximum load diagrams in the Manual & Tutorials section.

PERFECT GIFT FOR DAD: SAVE HIM HUNDREDS OF HOURS OF WORK!

EXTRA 10% OFF ON ALL ORDERS WITH COUPON CODE: LOVEDAD10

PROFESSIONAL LIFT TOOL FOR INDUSTRIES

365Famtools Labor Saving Arm - Hand Lifting Jack Tool is useful for installing doors, windows, cabinets, and appliances, as well as constructing porches, decks, flooring, and foundations. It reduces the number of hands required for installation work. Significantly enhancing efficiency for professionals in addition to reducing frustration among home improvers. Most importantly it saves time, money and your...back!

EXPLORE LABOR SAVING ARM

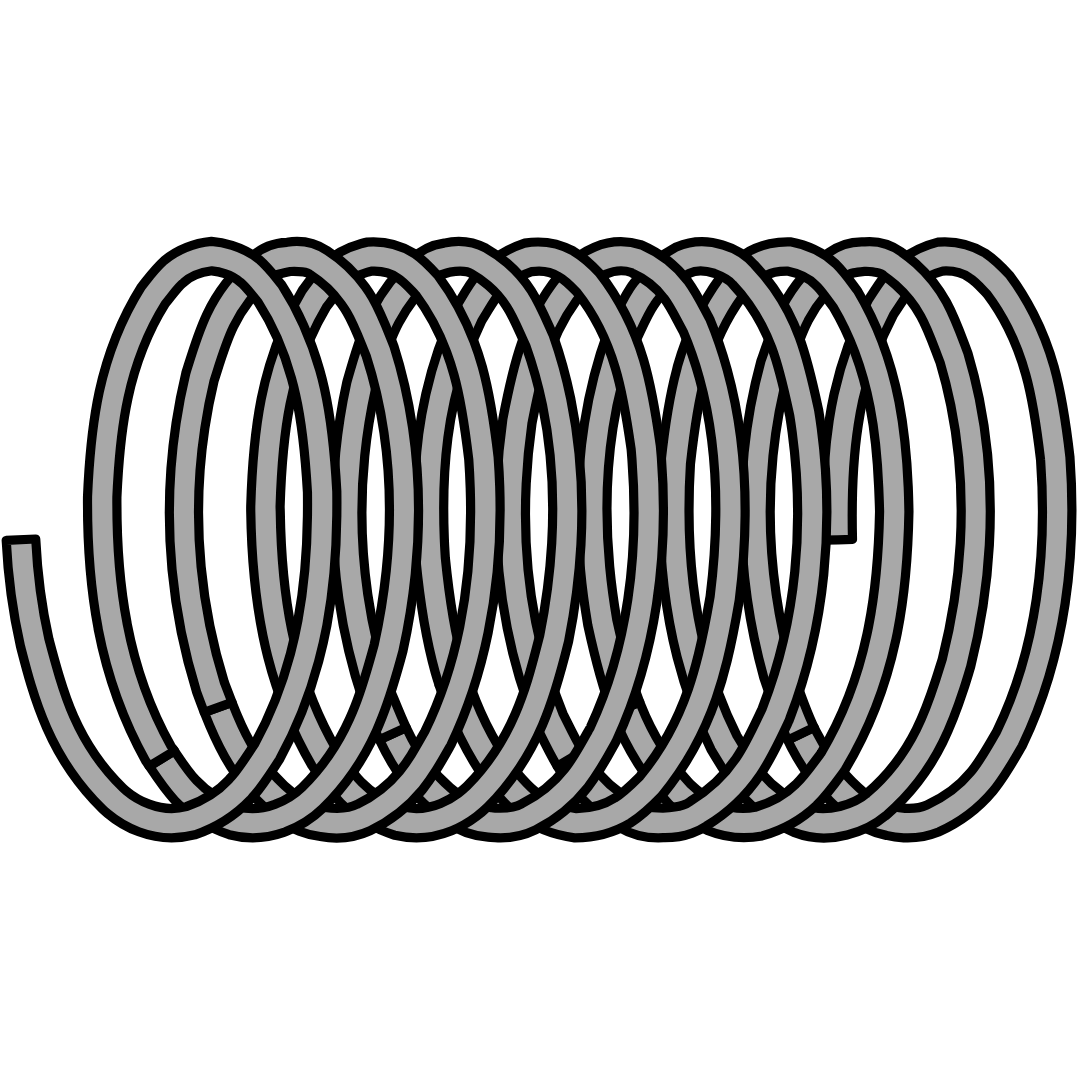

High-strength endurance spring

Lift up to 150kg / 330lb

Sturdy - ingenious handheld jack

Made of stainless steel durable and long service life

Adjusted height easily

Hold the handle, push & pull up repeatedly to increase the height

Lower the height

Gently press the top metal sheet to lower the height

- Product Specifications

- Product Packaging

Technical Specifications

Material:

Hardened stainless steel / Aluminum

Capacity:

Up to 150 kg = 330 lb

Operation range (mm):

6 - 215

Standard base (mm):

5 x 105 x 87

Optional base hardened steel (mm):

6 x 105 x 8

Optional base (mm):

3 x 77 x 62

Weight:

0.45 kg = 1,0 lb

What's in your package?

Your ordered product(s)

Paper Box

Nylon Cover

SPECIAL DEAL FOR FATHER'S DAY ONLY

WHY CHOOSE US

EASY TO USE, IMPRESSIVE EXPERIENCES

HAPPY CUSTOMERS LOVE 365FAMTOOLS™ LABOR SAVING ARM

Two-Man Job By One Person!

- Strong load-bearing (Lift up to 150kg / 330lb).

- Full steel base.

- High-strength endurance stainless steel spring.

- Adjusted height easily.

- Impressive capacity for a compact hand tool.

- Increases productivity, saves time and money.

FIND YOUR ANSWERS HERE

HOW HEAVY AN OBJECT CAN BE LIFTED BY LABOR SAVING ARM?

I HAVE BENT LIFTING BARS. WHAT CAN I DO?

Lifting an object weighing over 150 kg with one Labor Saving Arm may result in bent bars/base. Such use of the tool is not covered by our product warranty. You may remove bars/base and try to bend them back. If this doesn’t help, you can replace the bars/base. Please Send us a message if you need to order spare parts.

MY LABOR SAVING ARM MAKES A CREAKING NOISE. CAN I FIX IT SOMEHOW?

While creaking can be really annoying it doesn’t affect the Labor Saving Arm’s functionality. Actually, some craftsmen prefer to work with a “dry” tool. If you want to eliminate creaking, you may try to twist springs a bit first. If this doesn’t help, any quality technical lubricant will fix it.

HOW SHOULD I MAINTAIN LABOR SAVINNG ARM? CAN I REPAIR IT IF I EXPERIENCE ANY PROBLEMS?

It is important to maintain your Labor Saving Arm regularly. This will help increase the service life as well as the performance.

Your Labor Saving Arm should remain free of debris, sand, cement and dust, which can cause damage over a long time. It is well worth to spend a few minutes cleaning the tool compared to the cost of repairing or replacing it.

Cleaning the tool regularly is essential to their proper functioning. You can clean it by simply wiping all over with a rag. If the arm is dirty, do not hesitate to disassemble it, clean and lubricate all the parts properly. Please watch our Labor Saving Arm Assembly video in the Manual & Tutorial section.

Lubricate your Labor Saving Arm before you start using it and on a regular basis after that. Sprinkle metal parts with a light coat of any good industrial lubrication oil. Lubricating helps to improve performance of the tool, solve occasional loss of functionality, reduce wear and tear of components and prevent corrosion.

Regularly inspect your Labor Saving Arm for signs of damage and faulty functioning. Ensure that you repair your tool immediately if there is any damage.

WHEN WILL MY ORDER SHIP?

Orders are processed depending on item availability and payment approval. During high volume periods, product availability may be subject to change while your order is being processed.

Most orders placed on business days will be processed and shipped within 1-3 days (before delivery).

We are unable to deliver on weekends or public holidays, any orders placed during this period will be dispatched the following business day.

HOW LONG DOES MY ORDER TAKE TO ARRIVE?

Prior Delivery 4-7 business days / Standard Delivery 5-15 business days (after processing).

Please note that shipping times do not include the standard 1-3 business days processing time it takes for the order to ship out.

WHERE DOES 365FAMTOOLS SHIP FROM?

HOW DO I TRACK MY ORDER?

Once your order has been shipped, you will receive an e-mail notification containing the shipment tracking information. You will then be able to track your order through the tracking link on your email. Your order may arrive in several shipments. You will receive a separate e-mail notification for each shipment.

It will be sent to the email you used for placing the order. If you fail to track your order, please email support@365famtools.com with your order number and request.

HOW DO I CHANGE OR CANCEL AN ORDER?

You may change or cancel your order by our Customer Support Team before the order is processed.

If you miss this grace period, no worries! We are committing to ensuring that you find your perfect fit at Return & Refund Policy. If you want to change your order, we recommend placing a new order to ensure that you receive it as soon as possible.

WHAT SHOULD I DO IF I DID NOT RECEIVE MY DELIVERED PACKAGE?

First double-check the area where the carrier would have left it. Ask neighbors too in case the package was dropped at the wrong door. Also, look for any "attempted delivery" notices, which means the carrier tried to deliver it, but no one was home. If you still don’t see anything, wait until the end of the next day, because some carriers’ electronic systems may show the package as delivered, even when it’s still on the way. Still no luck? Call the carrier with your tracking number for more information.

If the carrier is unable to provide a resolution please contact our Customer Care Center at support@365famtools.com

Can't find an answer to your question?

Fell free to mail us at support@365famtools.com

Email: support@365famtools.com

Copyright © 2023, 365Famtools™ Design By 365Famtools Corp